ALFA LAVAL, Denmark, the world leader in boiler engineering and manufacturing, produce marine boilers, thermal oil heaters, cargo heaters, burners, inert gas systems and boiler automation systems. Through a series of acquisitions, ALFA LAVAL encompasses the organizations of Sunrod, Gadelius, Vesta, Wiesloch and Unex. The state-of-art technology along with the global presence of the ALFA LAVAL, explain the huge market share in the newbuildings undertaken by shipyards worldwide, including the Far East. Pivotal point of the ALFA LAVAL product range is the

MISSION series of boilers with new modular design, oil-fired and composite, in cylindrical and D-type execution for steam production up to 110 tons/hr.

A worldwide network of companies (Shanghai, Singapore, Dubai, Houston, Rotterdam etc) provide competitive after sales service including the supply of materials and labour, with highly specialized teams able to undertake a boiler repair anywhere in the world. Based on decades of experience and documentation on hundreds of different types of boilers, high quality repairs can be effected within tight time-constraints, providing competitive and effective solutions to the customer’s exact requirements.

Having supplied 38,000 boilers, ALFA LAVAL support their products with a life-time commitment proving true partners in operation.

In view of the implementation of the MARPOL ANNEX VI regulations, coming into force in 2015, the applicable Sulphur limit at Emissions Controlled Areas (ECA) will be reduced to 0.1%. While the worldwide Sulphur limit is to be reduced at 0.5%, effective from 1st of January 2020.

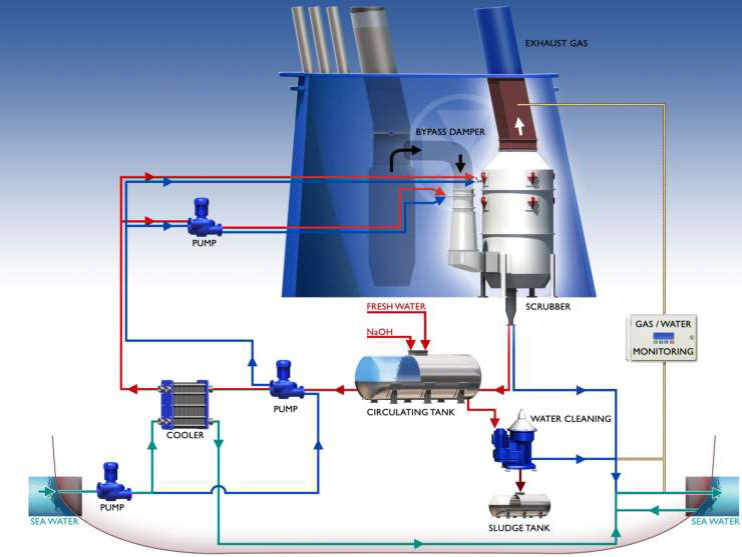

ALFA LAVAL has expanded their product portfolio by launching the PureSOx scrubber system, providing to ship-owners the benefit to continue operating on heavy fuel oil (HFO) instead of the considerably more expensive marine gas oil (MGO), while still meeting with IMO strict SOx emissions regulations.

With over than 40 year experience in supplying scrubber as an integrated part of inert gas systems.

PureSox “hybrid” system has been designed so as to accommodate operation in open sea (S.W. mode) and/or closed-loop operation (F.W. mode) whenever zero-discharge is required by port-authorities or sea-water alkalinity is not sufficient.

The world’s largest Scrubber installation, effected in 2009 onboard onboard the Ficaria Seaways, has already evidenced PureSOx capability to cope with low-alkalinity waters (i.e. Baltic) at minimized energy consumption pattern, achieving lowest operability cost along with smooth and trouble-free operation.