28/02/2024

ALLWEILER-IMO Highly reliable Three Screw Pumps for transferring fuels and lubricants

28/02/2024

ALLWEILER-IMO Highly reliable Three Screw Pumps for transferring fuels and lubricants

As environmental protection regulations become more stringent, innovative solutions in the pump industry are essential. ALLWEILER and IMO Three Screw Pumps are engineered, manufactured, serviced and supported to meet these unique demands of the Marine business.

The challenging situation since the introduction of the new low sulfur fuels and the repeated incidents have led operators to increase their standards in terms of quality when a replacement or upgrade is necessary.

Members of CIRCOR Group, ALLWEILER GmbH and IMO AB, two of the most reputable and well established Pump manufacturers, have been vastly chosen for their superior quality and well proven reliability to meet the new requirements.

With thousands of vessels operating globally with the ALLWEILER/IMO pumps and with over 100 years of experience, ALLWEILER and IMO can provide Owners with a wide range of pumps, covering all needs onboard the ships.

Going further, and recognizing the urgency in case of a defect, we have created an adequate stock of the most common pump types (ACE 032, ACE 038) available for immediate dispatch, at our warehouse in Piraeus.

Designed for the demanding marine environment and having more than one million pumps delivered worldwide, IMO ΑΒ is an established and trusted maker in the marine industry.

Viscosity range 1.4 – 5000 cst

IMO pumps meet the requirements for low viscosity (down to 1.4 cSt @ 40 0C for DMX) according to ISO 8217:2017 and max. sulfur content of 0.1% as stated in Marpol 73/78 and 2005/33/EC while maintaining the same high reliability.

Low Power Consumption

Small peripheral diameters of the rotors and low fluid axial velocities reduce fluid shearing within the pump, resulting in a reduction of horsepower consumption.

Benefits of simplicity

IMO pumps are simple to understand and with only three moving parts, there is little that can go wrong.

Designed for efficiency

IMO Pumps are designed using internal bearings which are also hydraulically balanced so that there are no loaded bearings, neither axial nor radial. These design features mean less maintenance for re-greasing, less downtime and longer life.

Leak-free

OptiLine (Magnetic Coupling) version, eliminates leakages by incorporating a complete enclosure where there is no shaft extension into open air and thus, no need for a conventional seal. Power transmission is achieved through the magnetic coupling.

Quiet operation

Smooth and continuous output flow that greatly reduces pressure pulsations. As a result, there is lower air borne, fluid borne and structure borne noise for a wide viscosity range.

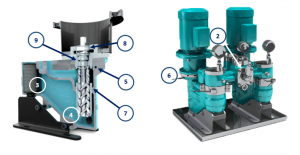

ALLFUEL® 3-Screw pump series with a delivery pressure up to 40 bars, is widely used for Fuel and Lubricating Oil Feed and Circulating pumps. They are capable of handling fuels with viscosities as low as 1,0 cst and having Sulfur content of 0,1% by mass.

Specifically designed for marine use, the ALLFUEL® series demonstrates the following key characteristics.

1. Compact Design: Less installation space is required, due to smaller overall dimension.

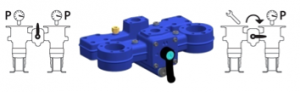

2. 100% Secure Change-Over: Modern valve casing, equipped with one ball valve and three clear valve positions, for secure switching to the standby pump. The non-return valve permits maintenance and dismounting of one pump without disturbing the operation of the other.

3. Fast exchange of Filter: Vertical installation of the filter allows an installation without oil drain. No risk of Dry-running after filter change. Due to the “inside-out“ perfusion the dirt particles stay in the filter.

4. Secure pump Operation: Nearly pulsation free and low noise operation.

5. Smooth pump starting: The optional heating for filters and mechanical seals guarantees a smooth pump starting with low ambient temperatures.

6. Ideal starting: A vent screw offers an ideal venting of the mechanical sealing room.

7. Additional O-Ring: For prevention of backflow of fluids with low viscosity (MGO).

8. External ball bearing: Wear protected and sealed.

9. Mechanical Seal: Wear-resistant SiC/SiC.

Relevant News